In response to the increasing use of two-axis machining systems, K&Y Diamond provides turning tools manufactured to exacting tolerances and strict quality control, which are essential for all electro-optic device applications. Our goal is to provide our clients with leading edge tools which achieve high quality surface finish on a large variety of materials.

Fly-cutting tools are also available and can be made according to your requirements.

What are the applications?

K&Y works in collaboration with many different sectors directly connected with the manufacturing of electro-optic devices and among them:

Infrared lenses

Photo receptor drums

Platters in Hard Disc Drives (HDD)

Mobile phone camera lenses

Digital devices

DVD & Blu-ray players

…and much more.

What materials are machined with K&Y Diamond tools?

K&Y Diamond creates turning,fly-cutting, milling, parting, and grooving tools suitable for all kinds of non-ferrous materials as well as certain crystals. New technologies allow us to offer fly-cutting tools that can be used on certain ferrous materials. Please, contact our professional teams to learn more about it.

Here is an overview of materials that can be machined with single crystal diamond:

Copper

Nickel

Aluminum

Gold

Brass

Carbide

Plastics

Zinc selenide, Zinc sulfide, Calcium fluoride, KDP, Germanium, Silicon etc.

Our strengths?

K&Y Diamond has the latest equipment for both producing diamond tools and for measuring them. By constantly investing into our techniques, we are truly redefining the edge. The Company is owned and driven by Rene Guillaume, and he has been working with diamond for more than 30 years now. Rene is constantly innovating and driving the company years ahead of the competition. Take advantage of our innovations that will assure you are using the most efficient and reliable tools that eliminate errors and reduce production costs.

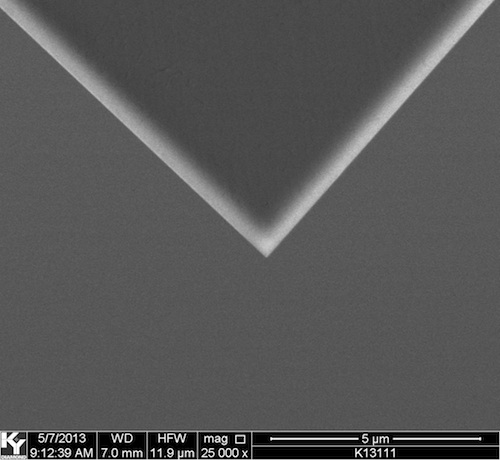

An outstanding magnification capacity

Before they reach our clients, our tools are inspected at a magnification ranging from 800x to 50,000x using a scanning electron microscope (SEM).

Another Strength: Non-standard tools

K&Y Diamond creates the tools you need with the shape you need, whether it is an elliptical shape, a concave radius tool, multiple radii on a tool……whatever you think you need, please check with us and chances are quite good that we can make it. When other manufacturers say “no, we can’t”, K&Y will usually say “yes we can”.

And so much more…

All our cutting tools are offered with a certificate of compliance.

We guarantee an optimal tool life.

We adapt our manufacturing to the technical specificities of your machining operations.

Our tools are available in solid-shank or insert-style system.

We manufacture standard or custom-made solutions for all your applications, from the most basic to the most complex.

K&Y Diamond puts its expertise into every tool we make. Please contact us to get a complete quote which always includes a drawing so there is never a doubt that you get exactly what you order!